Traditional stamps demanded messy ink pads and constant external re-inking. But modern self-inking stamps integrate internal long-lasting ink supplies to simplify repetitive usage. These all-in-one units streamline stamping with elevated consistency and versatility for diverse needs from professional marking workflows to crafting customization. This guide explores revolutionary self-ink specialty stamps eclipsing old limitations.

Basics of Self-Inking Stamps

Before surveying specialty stamp designs, first understand core self-inking components:

- Ink Pad Chamber- Internal ink-saturated pads supply endless stamping cycles without external re-inking needs. Advanced pads distribute the ink evenly with minimal future smudging.

- Stamp Die Plate- Etched impression plates transfer pad ink onto target surfaces. Plates come premade with dates, icons, etc, or customized using laser etching.

- Housing- Composite plastic casings fuse ink pads smoothly with etching dies preventing internal leaks while allowing external stamping pressure shifts.

Together this compact all-in-one system provides key advantages over legacy wood mounts requiring separate ink pads:

- No Exterior Inking- Built-in internal supplies enable rapid repetitive marking without re-inking.

- Portable & Protective- Compact integrated construction travels easily without leaking and allows shielding dies when not active.

- Comfort Grip Handles- Ergonomic hold points maximize stamping pressure control and handling comfort during repetitive manual usage cycles.

- Economical Supplies - Only internal pad refills require infrequent changing instead of buying replacement Stamp mounts.

- Customizable Dies- Etch any symbols or lettering onto plate dies for completely personalized impressions.

Now with basic handle-enclosed self-ink stamp fundamentals covered, let's survey specialty varieties optimized for diverse applications.

Types of Self-Inking Stamps

Standard all-purpose stamp versions maximize multi-surface versatility. But enhanced designs cater to specific frequent scenarios:

1. Pre-Inked Stamp Pads

Pre-inked self-ink stamps undergo additional ink saturation before final factory assembly. This maximizes initial impression longevity by over-saturating internal supplies with extra ink volume distributed through microscopic porous pads.

The extra prep step ensures crisply defined fine text and intricate logos render perfectly when other pads eventually transition towards fading "ghost mark" impressions as ink incrementally depletes over tens of thousands of cycles.

Pre-inking adds minimal expense for notably extended usage spans between requisite internal pad replacements. For high-frequency consistency like business dates, pre-inking is well worthwhile.

2. Date and Time Stamps

Tracking documentation timing proves essential across sectors from legal services to shipping departments. Self-ink date stamps allow adjustable date dials or digital interfaces for perfectly synchronized automatic timestamps rather than inconsistent manual date entries prone to human error.

Beyond establishing authenticity, embedded date/time marks significantly aid organizations. Some models even integrate ordinary timekeeping into date stamps for portable consolidation.

Dual-function editions with chronometric displays empower employees, officials, artists, and hobbyists alike. Never question document timing again!

3. Custom Design Services

Beyond pre-made self-inking seals and practical time tracks, an emerging option is complete custom-stamped art creation. Transform meaningful mottos into professional signature marks or just embellish personal items and gifts thanks to low-cost rapid prototyping.

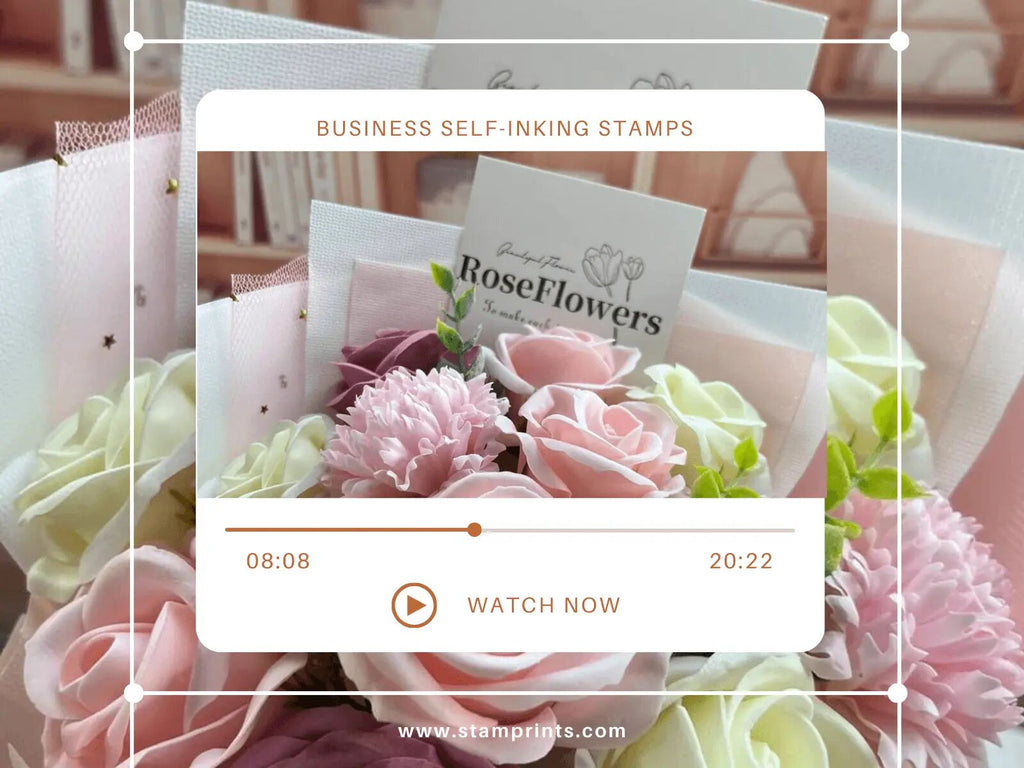

Online design platforms, such as Stamprints, allow the effortless embedding of custom text, logotypes or decorative scrollwork into laser-etchable stamp die plates. Completed stamp units arrive within days to flexibly mark nearly anything imaginable with personalized authority.

For ultimate versatility, complement customized self-ink stamps with specialty quick-dry inks compatible across uncommon materials detailed next!

Factors to Consider When Choosing Your Self-Inking Stamps

When selecting a customized self-inking stamp imprinting precise markings thousands of times without external maintenance, multiple key factors require consideration to avoid hasty purchases failing prematurely.

1. Design and Dimensions

Consider the specific text, logos, or artwork that needs to be included on the stamp imprint. Assess the available customization options to ensure all necessary details can be accurately incorporated into the stamp plate engravings. Prioritize readability by choosing appropriate type sizes big enough for legibility, especially important for company branding elements to maintain a clear visual identity. Also, ensure the overall stamp size dimensions allow for full impressions without incomplete markings.

2. Construction and Durability

Self-inking stamp bodies precision-engraved into durable polymers offer resilient stability over extended repetitive usage. The hardened plastic withstands impression pressure cycles over years without distortion or fading that gradually degrades delicate rubber stamp mountings with heavy use. Polymers also better transfer pad inks onto the paper stock for consistent stamps even when wet ink re-saturation eventually becomes necessary down the road. For longevity even with daily use, polymer endures.

3. Ink Pad Performance

The integrated self-contained ink pad consistently channels just enough vivid pigment or dye-based ink to paper with every mark. Advanced material formulations include porous cushioning membranes that compress under imprint force, feeding ink evenly before rebounding without flooding documents. Seek water-fast fade-resistant ink that remains flexible without drying or crusting while sealed by the internal supply reservoir.

4. Intended Usage Factors

While generic light-duty stamps allow affordable incidental functionality like date markings, custom engraved self-ink stamps designed for repeated pressings are wise investments for permanent installation within fast-paced work environments. Consider supplemental features like pre-inked supplies, ergonomic grip shaping for long stamping periods, orbital shaking disks ensuring even ink redistribution, and premium ink viscosity or padded impressions lasting over 100,000 uses between routine long-term maintenance.

How to Maintain Self-Inking Stamps

Preserving stamp functionality through conscientious maintenance guarantees longevity curtailing avoidable replacement:

1. Cleaning Protocols

Follow manufacturer guidelines for cleaning engraved die plates using ink solvents and soft brushes to dissolve residue buildup around etched impressions compromising marking clarity without damaging plates.

Isopropyl alcohol formulas with under 30% dilution ratios work sufficiently for most buildup cleared using gentle directional bristled brush scrubbing.

For rapid cleaning between sporadic stamp presses, peeled sticky adhesives like Post-It notes lift debris quickly when brushed across engravings.

2. Ink Pad Re-Saturation

Once faint impressions indicate drained internal ink pads after estimated cycle lifetimes, inject replacement ink directly into the padded chamber rather than discarding entire stamp bodies needlessly.

Universal stamp inks populate markets for most consumer models allowing economical refilling using basic pipettes and blunt needles rather than costly proprietary cartridges. DIY ink blending kits also empower tweaking personalized colored, glitter, or glow-in-the-dark ink!

Meticulous re-saturation prevents air pockets from forming underneath pads producing temporary voids in coverage and uneven ink distribution. Slow presses afterward rebalance absorption.

3. Storage Best Practices

Between active usage periods, store stamps with pads facing upwards to mitigate gravity gradually pooling ink only along bottom pad edges. This prevents starved partial impressions.

Additionally, cover stamps using included plastic caps or craft foam to prevent ambient debris from accumulating across etching plates during storage in bags or drawers.

Finally, avoid direct sunlight exposure and extreme temperature swings degrading chemical ink properties through breakdown over time.

By cleaning plates, refilling dried pads frugally, and storing sufficiently protected during dormancy, investments sustain years of reliable functionality.

Get Creative With Custom Marks

Beyond boring legal disclaimers or routinely marking paperwork, revolutionary print personalization potential exists for enterprising innovators.

1. Promotional Products

Amp up merchandising memorability by supplementing promotional giveaways with branded freebie custom self-ink stamps for fans. Events distribute custom logo stamps rather than common stickers to engage attendees uniquely while low-cost scale events.

2. DIY Stationery

Print invitations, thank you notes, and correspondence ubiquitously featuring consistent monograms or decorative edges for upscale cohesion. Bring concept stationery suites sold commercially into affordable reach augmenting uniqueness.

3. Wearable Customization

Unleash clothing customization potential by combining fabric ink pads for marking tee shirts with iron-on transfer sealants permanently setting wash-proof personalized prints as long-lasting ironed-on patches.

The applications are practically endless once envision the customization power made accessible and affordable courtesy of revolutionary modern self-ink stamps. Apply imagination – then leave your mark!

Unlock Modern Markings via Self-Inking Stamps

Self-inking stamps revolutionized functions from branding to workflows by integrating long-lasting ink pads internally, eclipsing external re-inking limitations of conventional stamps. This guide outlined all-in-one specialty stamps elevating repeatable precision across diverse surfaces with cost-efficiency. With insights on optimal components, ink pairs, and maintenance, optimize unique markings for professional or creative outlets! Keep discovering novel stamping approaches to leave your efficient personalized mark.